Greenkeeping Efficiency

The Crucial Role of Tyre Sealant Maintenance as we move into Spring The grass is growing, and the blossom is

The Crucial Role of Tyre Sealant Maintenance as we move into Spring The grass is growing, and the blossom is

EASTER OPENING TIMES We’ll be closed for the Easter weekend. But don’t worry, it won’t be for long, we’ll be

Every day we talk to customers about the financial impact of tyre blowouts on not just them, but also on

The Dunster Show, situated on the edge of Exmoor National Park on the lawns below Dunster Castle, provides a unique

Air-Seal Products exhibited at one of the largest one-day agricultural shows in the country this month – The Honiton Agricultural

Air-Seal Products had the pleasure of supporting one of our trade customers, Harpers Feeds, at Yealmpton Show on the 26th

The Air-Seal Products team exhibited at a very wet and muddy Mid Devon Show on the 22nd of July. The

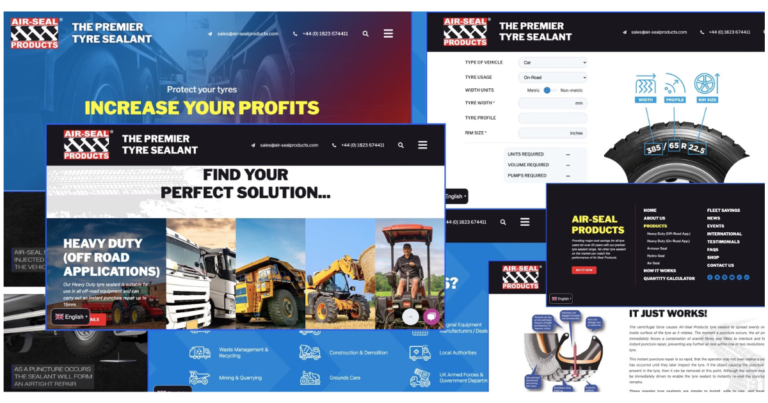

Air-Seal Products are proud to announce the launch of our brand-new website, providing customers with an enhanced online experience and

The automotive industry has faced various unprecedented challenges over the last few years due to Covid-19, Brexit and supply chain

Out of 2,000 UK drivers, only 14% described tyres as the most crucial safety feature on their cars in a

Air-Seal Products had a busy few days at The Commercial Vehicle Show at the NEC in Birmingham last week. The show is the

Electric vehicles (EVs) appear to have the upper hand over Hydrogen vehicles at present, though this could be explained by

Providing major cost savings for all tyre users for over 20 years with our premier tyre sealant range. No other tyre sealant on the market can match the performance of Air-Seal Products.