how it works

It just works!

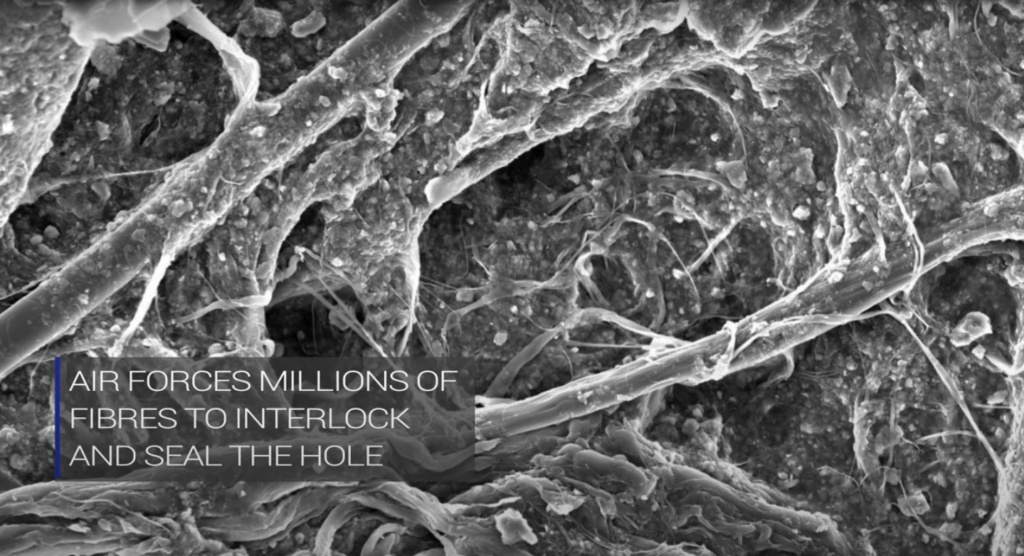

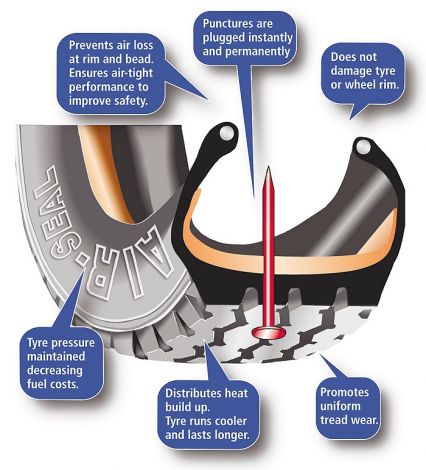

The centrifugal force causes Air-Seal Products tyre sealant to spread evenly over the inside surface of the tyre as it rotates. The moment a puncture occurs, the air pressure immediately forces a combination of aramid fibres and fillers to interlock and form an instant puncture repair, preventing any further air loss within one or two revolutions of the tyre.

This instant puncture repair is so rapid, that the operator may not even realise a puncture has occurred until they later inspect the tyre. If the object causing the puncture is still present in the tyre, then it can be removed at this point. Although the vehicle must then be immediately driven to enable the tyre sealant to instantly re-seal the puncture that remains.

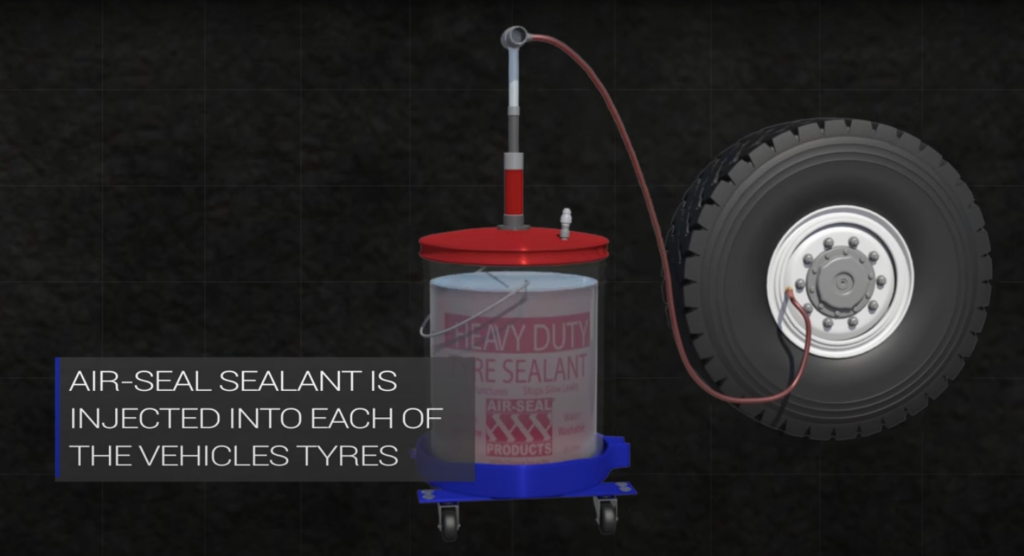

These premier tyre sealants are simple to install, safe to use, and have been independently tested across the entire globe. Depending on the grade of tyre sealant used, punctures up to 30mm (1¼ inches) in diameter, can be instantly repaired using this technology.

what makes us unique?

Fibres

Fillers

Stability

The strength of the fibres used within a tyre sealant will determine how strong the puncture repair is. The aramid fibres chosen by Air-Seal Products are some of the strongest, and most abrasion-resistant, synthetic fibres to date, like the state-of-the-art fibres used in tyre cord and bullet proof vests. Thanks to the varied length and degree of branching of the fibres contained within our tyre sealant, the puncture repair can occur instantly and will last the life of the tyre.

Once a strong puncture repair has been formed by the fibres within the tyre sealant, the final seal is provided by the filler particles. These particles are imperative for a high-performance tyre sealant as they lodge between the fibres within the puncture site to form an effective airtight plug.

The only purpose of the liquid portion of the tyre sealant formation is to carry the critical fibres and fillers to the penetration site to perform an instant puncture repair. If the components within a tyre sealant separate, then it will not perform effectively. Air-Seal Products tyre sealant range has been specifically formulated to overcome this and therefore has an indefinite shelf life and can even be reused.